Controlling Sulphur content in the material is very critical when it comes to orbital welding. Both high and low sulphur in the tubes lead to unacceptable weld quality. Our range of tubes with EN 1.4404 & 1.4435 that comes with controlled sulphur range from 0.005 – 0.017, an ideal fit for orbital welding and this application

Eliminate cost escalations due to the forex

fluctuations and banking formalities. Save on

Bank charges, forex, agent commission etc.

No need to order in bulk. Save on inventory and

handling costs as you order as much as you

require.

A fully automated line and ex-stock inventory

enables us to deliver tubes shorter lead times.

Eliminate custom clearance or shipping delays. You get the

tubes when and where you want it delivered to your door steps.

We ship 6.1 Mtrs EP tubes whereas locally NON – EP imported tubes

are electropolished in 3 mtrs length. Savings on transportation cost

accrued due EP transportation.

FAT can be conducted before taking delivery.

Not possible when you import. The cost of tube

replacement, delivery issues are eliminated for

good.

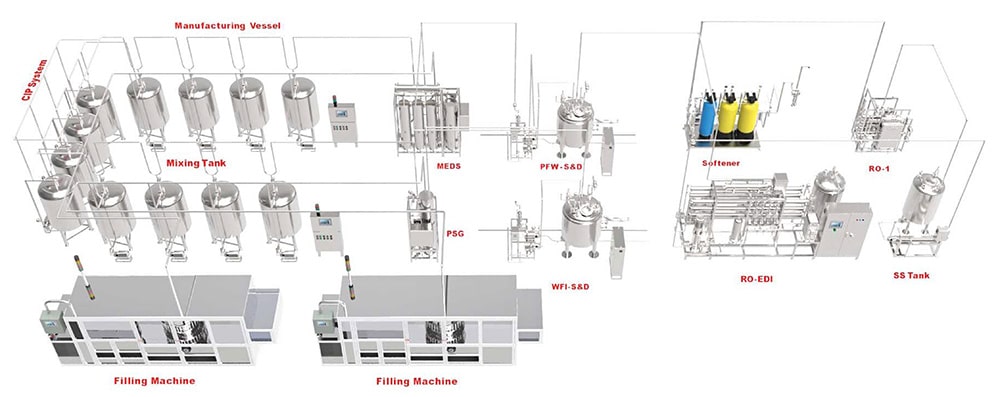

| Grade & Surface Finish | |||||||

|---|---|---|---|---|---|---|---|

| Application | Grade | Surface Finish | Finish Value Ra (μm) | Finish Value Grit | |||

| ID | OD | ID | OD | ID | OD | ||

| Product / Process (Carbonated) | 304 L / 1.4307 | MP | MP | < 0.5 | < 0.8 | >180 | > 150 |

| Product / Process (Fruit based, Non-carbonated) | 316L / 1.4404 | MP/EP | MP | < 0.5/0.38 | < 0.8 | >180/240 | > 150 |

| CIP / Soft water | 316L / 1.4404 | BA/MP | MP | < 0.8/0.5 | < 0.8 | >150/180 | > 150 |

| Treated water | 304L / 1.4307 / 316L / 1.4404 | MP | MP | <0.5 | < 0.8 | >180 | > 150 |

| Chilled water / Compressed air | 304 L / 1.4307 / 316 L / 1.4404 | BA | MP | < 0.8 | < 0.8 | >150 | > 150 |

609, Sanket Heights,

Sun Pharma Road,

Vadodara – 390 020.

Gujarat, INDIA.

Telephone : +91 8347 000 368

WhatsApp : +91 8347 000 368

Email : marketing@rensatubes.com

Plot No. 13 & 14

Jhagadia G.I.D.C.,

Bharuch – 393 110.

Gujarat, INDIA.

WhatsApp : +91 8347 000 368