Stringent, uncompromising quality standards sets us apart. We understand the critical nature of the fluids that our tubes carry. Every batch of tubes are subjected to rigorous test of both destructive and non-destructive in nature at every stage. This ensures only the qualified tubes pass on to the next stage. A well organized document plan ensures every tube, if required, can be tracked back to every stage in its manufacturing process and finally to its melt in the mill. A well trained and committed quality assurance and documentation team ensures strict adherence to laid out quality plan.

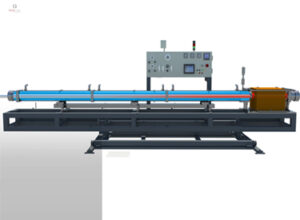

We manufacture the finest quality of Stainless Steel EP fittings, Electropolished stainless steel tubing for the critical applications for Pharma & Bio-Pharmaceuticals, Food & Beverages,Dairy and Healthcare & Cosmetics in a fully automated European tube production line under stringent quality control standards. The raw material, sourced from Europe are of international standards.

For over 10 years, our commitment to quality and customer service standards has been Unwavering in Stainless Steel EP fittings, Electropolished stainless steel tubing. Our mission is to provide hygienic and ultra-high purity stainless steel tubes for various sterile, aseptic and sanitary applications by complying with various global standards and specifications. It’s critically important to choose the right quality of Stainless Steel EP tubes, Stainless steel EP fittings that get installed in the fluid transfer lines. Our technological know-how combines with our experience results in the production of stainless steel tubes of the highest quality comparable to the global standards.

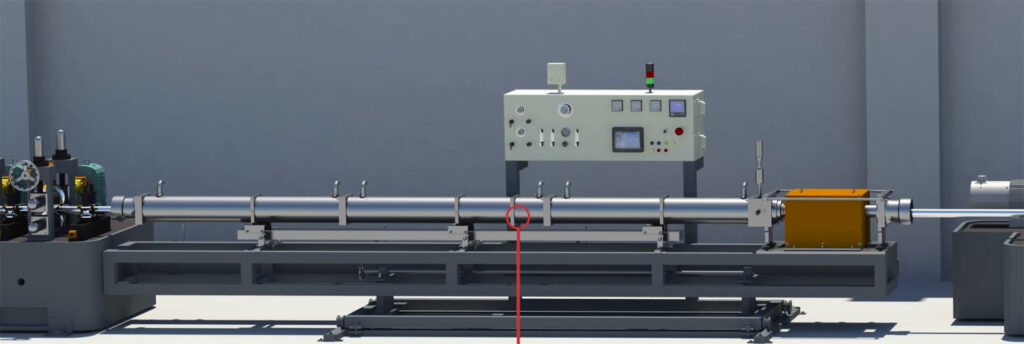

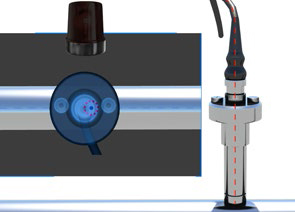

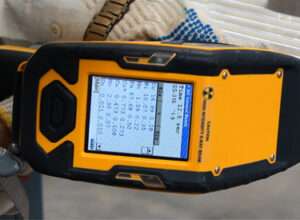

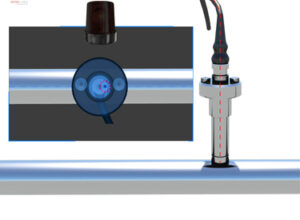

Our quality control laboratory is equipped with modern machines that enable complete in-house

testing of our tubes, using both destructive and non-destructive testing methods. Every batch of

tubes undergoes stringent testing and qualifies to be certified only after it passes 14 quality tests

that include both destructive and non-destructive testing. Stringent parameters are laid down for

each test and the results are documented and archived for traceability. All tests are carried out as

per ASTM / ASME standards.

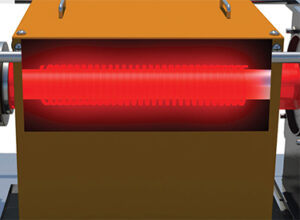

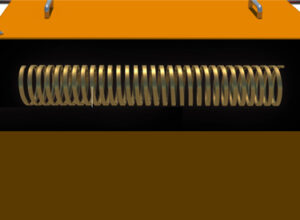

Bright annealing is a solution-annealing operation performed in a vacuum or controlled atmosphere containing hydrogen, in order that oxidation is reduced to a minimum and the stainless steel tube surface remains relatively bright. Aside from a bright surface, the oxide layer is very thin after this type of annealing.

The tube is not pickled afterwards as this is not necessary – and pickling can also potentially damage the oxide layer. As pickling is avoided Bright annealed tubes almost retain their original parent material which helps us to get surface finish below 0.8 μm even on weld seam. As a result, with a cleaner and brighter appearance and a controlled inside-surface condition, bright annealed tubing has a much smoother surface which imbues the component with better resistance to pitting corrosion.

Overall, the bright annealed and surface-finished tube has considerably better corrosion resistance compared to the open annealed and pickled tubes.

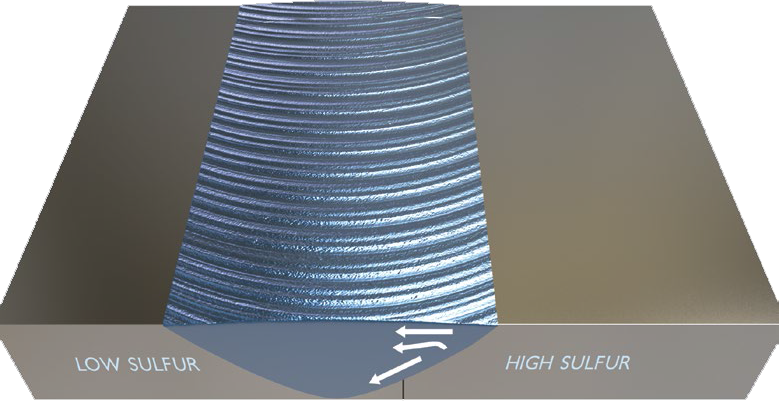

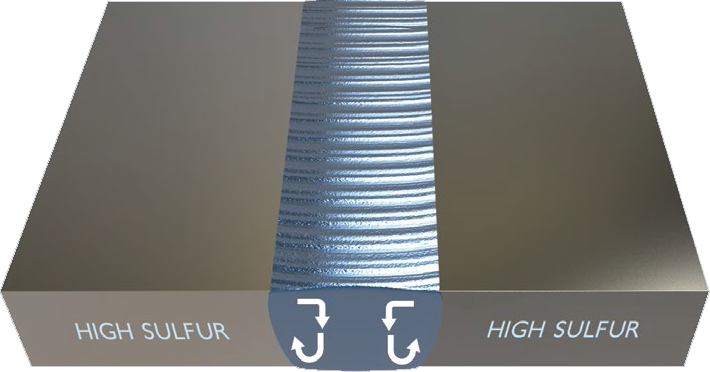

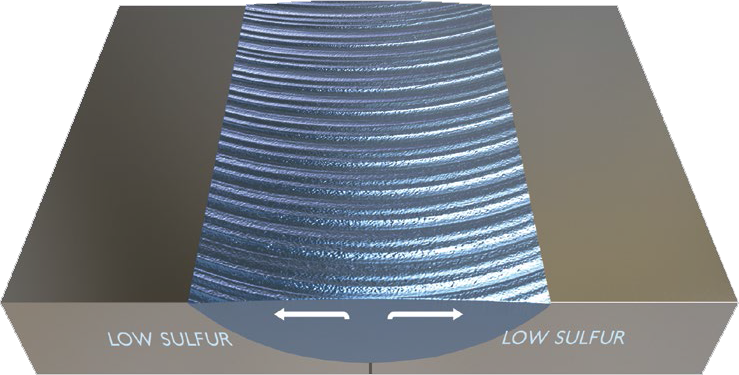

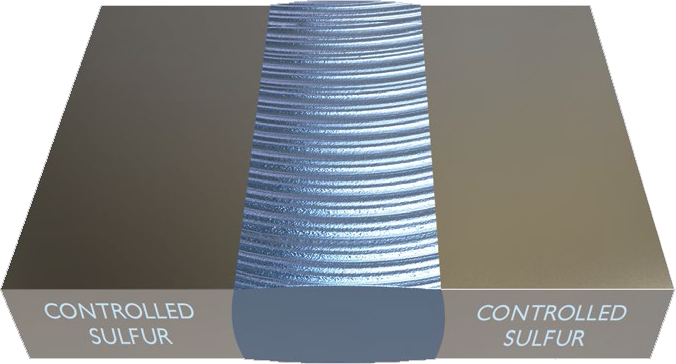

The widespread use of autogenous (fusion) orbital gas tungsten arc welding (GTAW) in the high-purity, semiconductor and biopharmaceutical industries, is both desirable and necessary to provide for 316L stainless steel with a controlled range of elemental Sulphur. Both the American Society of Mechanical Engineers (ASME) Bioprocessing Equipment Standard (ASME-BPE), which specifies materials for use in bioprocessing equipment, have chosen to specify type 316L stainless steel with controlled ranges forSulphur. The ASME BPE standard limits the sulphur concentration to 0.005-0.017 weight percent

When it comes to the stringent process of Biopharmaceutical applications, roughing is a major constraint. We offer EN 1.4435 grade of steel which is of low Ferrite and high Chromium, Nickel and Molybdenum composition. This decreases the chances of roughing in the system.

609, Sanket Heights,

Sun Pharma Road,

Vadodara – 390 020.

Gujarat, INDIA.

Telephone : +91 8347 000 368

WhatsApp : +91 8347 000 368

Email : marketing@rensatubes.com

Plot No. 13 & 14

Jhagadia G.I.D.C.,

Bharuch – 393 110.

Gujarat, INDIA.

WhatsApp : +91 8347 000 368