Rahul Ferromet & Engineering Pvt Ltd manufactures Hygienic & Ultra high Purity stainless steel tubes under brand name of rensa having its manufacturing facility at Jhagadia,Bharuch, Gujarat, India. With over 17 years of manufacturing experience, the 20,000 m2 integrated manufacturing facility with over 300 committed and dedicated team of employees has a capacity to produce 200,000 mtrs / month of high quality stainless steel tubes with complete traceability and documentation.

We manufacture high quality stainless steel electropolished tubes for Pharmaceuticals, Bio-pharmaceuticals, Healthcare & Cosmetics, Food & Beverage and Dairy industries. For over 17 years, our commitment to quality and customer service standards has been unwavering. Our mission is to provide hygienic and ultra-high purity stainless steel tubes for various sterile, aseptic and sanitary applications by complying with various global standards and specifications. Its critically important to choose the right quality of tubes that get installed in the fluid transfer lines. Our technological know-how combines with our experience results in the production of stainless steel tubes of the highest quality comparable to the global standards.

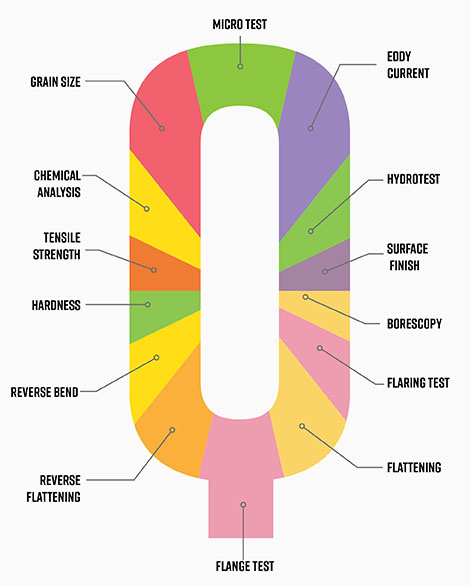

rensa comes with the commitment and assurance of the highest quality. Our stringent quality systems, technological know-how, innovation and our commitment to customer satisfaction are our key drivers. Our manufacturing facility is certified with ISO 9000-2008 and 3-A sanitary certification from USA. Every batch of tubes passes through a spectrum of 14 tests, that are both destructive and non-destructive types. Though a robust quality culture ensures we uphold our customers trust on our products, we continue to build and strengthen a culture of compliance & assurance, where every employee is trained to be vigilant and dedicated to the very highest standards of quality expected.

1 | TRACEABILITY

All tubes are marked with heat number on its surface. A well organized documentation plan ensures every tube can be tracked back to every stage of manufacturing.

2 | QUALITY RAW MATERIAL FROM REPUTED MILLS

We source our stainless steel strips from Reputed Mills. A company of global repute, trusted worldwide.

3 | EX-STOCK AVAILABILITY

We have ex-stock availability of almost all sizes grades and surface finishes. Option to order even small quantities as required.

4 | GLOBAL STANDARDS

Our tubes conform to ASME-BPE, 3A, ISO-SMS & BS 4825 standards with ASTM-A 270 specifications..

5 | 14 MANDATORY TESTS

Every batch of tubes undergo 14 mandatory quality tests for assured quality in consistency.

6 | CERTIFICATIONS & ACCCREDITATIONS

We manufacture tube for the global market. We are certified/ accredited with ISO 9001:2008 , 3A , PED 91/23/EC , AD 2000 MERKBLATT-W0, .

609, Sanket Heights,

Sun Pharma Road,

Vadodara – 390 020.

Gujarat, INDIA.

Telephone : +91 8347 000 368

WhatsApp : +91 8347 000 368

Email : marketing@rensatubes.com

Plot No. 13 & 14

Jhagadia G.I.D.C.,

Bharuch – 393 110.

Gujarat, INDIA.

WhatsApp : +91 8347 000 368