Rensa are manufactured with Bright Annealing Technology instead of conventional open furnace Solution Annealing & Pickling method. Pickling is done with very harsh chemicals which damages the tube surface and is also harmful to the environment. As compared to Pickled tubes, the Bright annealing process gives very minimal level of oxidation on the surface, provides relatively much brighter tube surface and maintains inside tube surface finish below 0.8 μm even on welding seam. As a result, with a cleaner and brighter appearance and a controlled inside-surface condition, bright annealed tubing has a much smoother surface which imbues the component with better resistance to pitting corrosion.

Rensa tubes are approved Stainless Steel Dairy Fittings Manufacturers in India. We are dealer & distributor of Dairy Fittings, Dairy Pipes, Sanitary Tube Fittings, Stainless Steel EP tubes at Factory Price due to reasonable man hours in India and good source of high quality Dairy Fittings Manufacturers at best price available in Mumbai, India. We supply and export SS 304L Dairy Fittings throughout the world in both imperial and metric sizes. Sanitary Tube Fittings also available in Grades 304/304L and 316/316L. Century Steel supply in 1/4” O.D. – 8” O.D., 1/4” N.B. – 8” N.B. Outside diameter .

So, if you are looking for best price of Dairy Fittings, Dairy Pipes, Sanitary Tube Fittings, Stainless Steel EP tubes near you with the shortest time delivery or free sample of Dairy Fittings, Dairy Pipes, Sanitary Tube Fittings, Stainless Steel EP tubes.

Eliminate cost escalations due to the forex

fluctuations and banking formalities. Save on

Bank charges, forex, agent commission etc.

No need to order in bulk. Save on inventory and

handling costs as you order as much as you

require.

A fully automated line and ex-stock inventory

enables us to deliver tubes shorter lead times.

Eliminate custom clearance or shipping delays. You get the

tubes when and where you want it delivered to your door steps.

We ship 6.1 Mtrs EP tubes whereas locally NON – EP imported tubes

are electropolished in 3 mtrs length. Savings on transportation cost

accrued due EP transportation.

FAT can be conducted before taking delivery.

Not possible when you import. The cost of tube

replacement, delivery issues are eliminated for

good.

| Grade & Surface Finish | |||||||

|---|---|---|---|---|---|---|---|

| Application | Grade | Surface Finish | Finish Value Ra (μm) | Finish Value Grit | |||

| ID | OD | ID | OD | ID | OD | ||

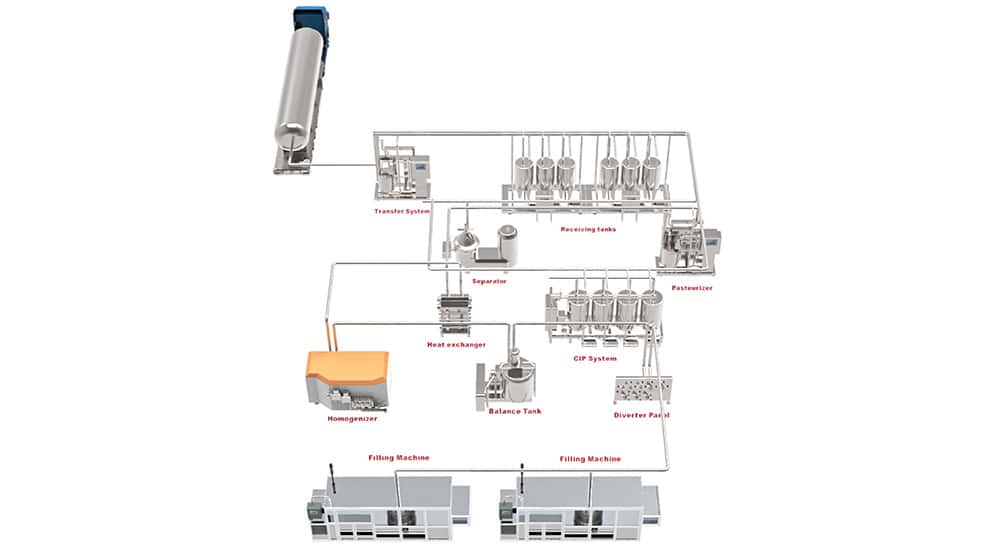

| Milk transfer | 304 L / 1.4307 | MP/EP | MP | < 0.5/0.38 | < 0.8 | >180/240 | > 150 |

| Process | 304L / 1.4307 | MP/EP | MP | < 0.5/0.38 | < 0.8 | >180/240 | > 150 |

| CIP system [cleaning solution] | 304L / 1.4307 | BA/MP | MP | < 0.8/0.5 | < 0.8 | >150/180 | > 150 |

| Auto / Manual milking systems | 304L / 1.4307 | BA/MP | MP | < 0.8/0.5 | < 0.8 | >150/180 | > 150 |

| Water/Chilled water /Compressed air | 304 L / 1.4307 / 316 L / 1.4404 | BA | MP | < 0.8 | < 0.8 | >150 | > 150 |

609, Sanket Heights,

Sun Pharma Road,

Vadodara – 390 020.

Gujarat, INDIA.

Telephone : +91 8347 000 368

WhatsApp : +91 8347 000 368

Email : marketing@rensatubes.com

Plot No. 13 & 14

Jhagadia G.I.D.C.,

Bharuch – 393 110.

Gujarat, INDIA.

WhatsApp : +91 8347 000 368