BIO

PURE

?Biopure comes with full traceability ensuring transparency and reliability throughout the manufacturing process.

Total compliance with ASME-BPE standards is our commitment.

Small Quantities accepted, Short Lead Times, Ex- Stock Availability, and Timely Delivery for all your SF4 and SF1 product needs.

We take environmental responsibility seriously. Our manufacturing processes are designed to be environmentally friendly, reducing our carbon

BIO

PURERensa takes immense pride in presenting our premium range of pharmaceutical products BioPure, our premium line of stainless steel tubes and fittings meticulously engineered to not only meet but surpass the highly specialized surface finishing requirements of the BPE industry, precisely outlined in the ASME BPE 2022 standards. The SF1-SF3 and SF4-SF6 (EP) products exhibit properties that challenge the best-in-class.

BioPure tubular products undergo a meticulous multiple- step cleaning process, ensuring pristine surfaces both inside and out with consistent repeatability.

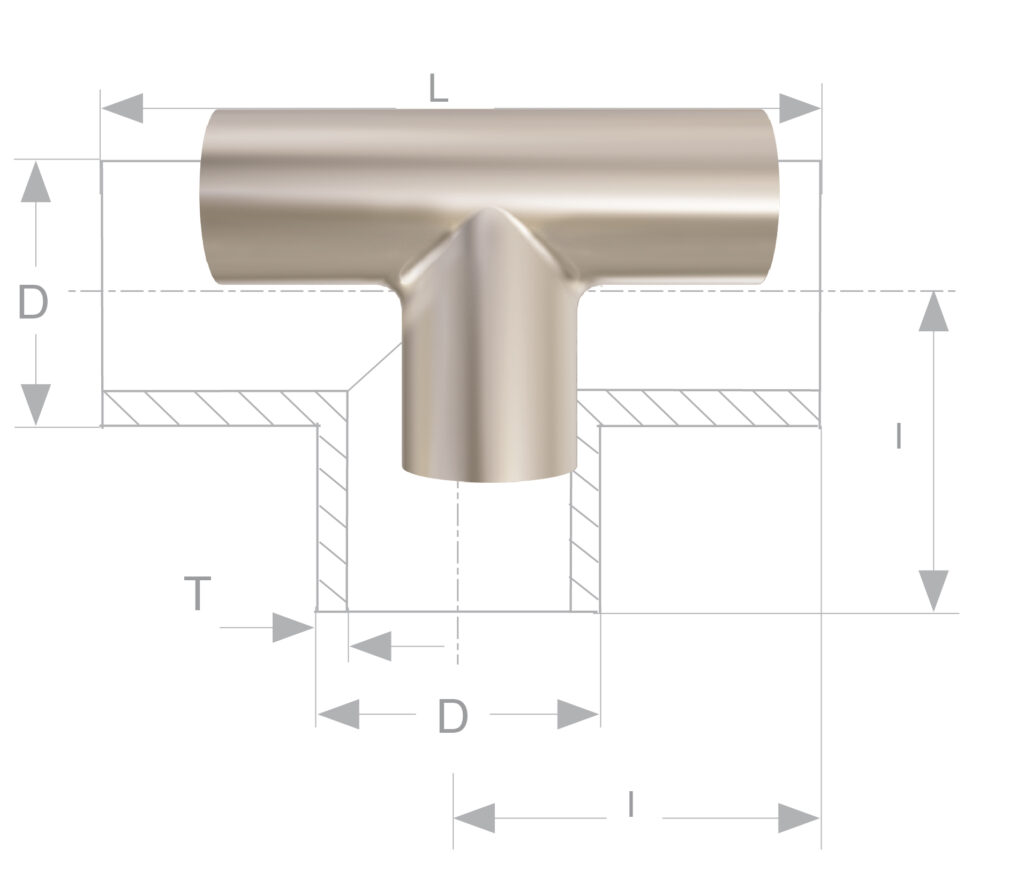

All fittings produced by Biopure production are 100% visually inspected for any surface finish Irregularities. All dimensional characteristics are inspected for tolerances listed in parts DT-4-1 to DT-4.1.5-2 in the ASME BPE specification.

Each fitting is capped, bagged and labeled in full compliance with the ASME BPE standard.

Full material test reports are supplied with the finished products and are available on our website.

BIO

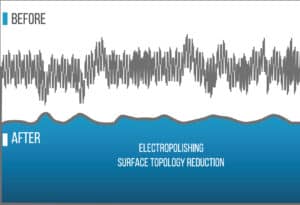

PURERensa’s electropolishing process is meticulously engineered to not only meet but surpass the stringent surface finishing requirements of the BPE industry, precisely outlined in the ASME BPE 2022 guidelines. Our SF4 -SF6 (EP) Biopure products exhibit properties that challenge the best-in-class.

Electropolished products are the preferred choice for numerous applications due to its outstanding surface smoothness, creating fewer sites for impurities. This translates to a purer product for the industry, with reduced risks of corrosion and bio-film formation.

BIO

PURE ADVANTAGEElectropolishing dramatically reduces micro roughness by dissolving metal ions faster at exposed peaks, Leading to lower Ra values, although most important is the smoother surface topography.

Electropolishing, an advanced electrolytic process, employs a combination of electrical current and electrolytes to remove upper surface layers of the material. The process effectively dissolves peaks and other surface irregularities by non-impact methods exposing the pure crystalline structure of the material, resulting in a remarkably smooth surface. Our in-house electropolishing facility has been developed and built by our technical team is overseen by our well-trained and experienced quality assurance team. Our mechanical polishing process involves an abrasive material, mounted on a special polishing head, rotates continuously within the product, achieving the desired interior surface finish. A controlled surface layer is meticulously removed during the process. Before undergoing visual inspection and final surface measurement, the product undergoes thorough cleaning through our in-house specialist cleaning and passivation systems.

609, Sanket Heights,

Sun Pharma Road,

Vadodara – 390 020.

Gujarat, INDIA.

Telephone : +91 8347 000 368

WhatsApp : +91 8347 000 368

Email : marketing@rensatubes.com

Plot No. 13 & 14

Jhagadia G.I.D.C.,

Bharuch – 393 110.

Gujarat, INDIA.

WhatsApp : +91 8347 000 368