Stainless Steel EP Tubes are widely used in various industries, from pharmaceuticals to petrochemicals, due to their exceptional strength, durability, and corrosion resistance. But have you ever wondered about the process behind their creation? The science and art of manufacturing these high-performance tubes is a complex and fascinating one, involving cutting-edge technology and skilled craftsmanship. In this blog post, we will delve into the world of Stainless Steel EP Tubes and uncover the manufacturing process behind these essential components, as well as the important role played by manufacturers of EP Tubes in creating them.

Stainless steel Electropolished (EP) tubes are a powerhouse in many industries, like pharmaceuticals, semiconductors, biotech, and food and beverage, due to their high purity and corrosion resistance. This dynamic combination makes them a reliable solution for systems that require extreme hygiene and high performance. The electropolishing process ensures a flawless finish, reducing the probability of bacterial growth and contamination. This makes stainless steel EP tubes not only versatile but also crucial for many high-stakes applications.

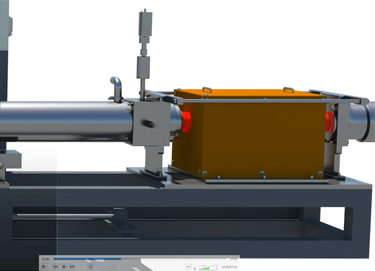

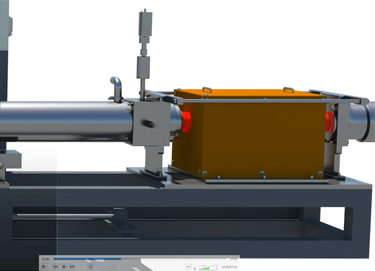

The journey of crafting a stainless steel EP tube begins with transforming a flat steel strip into a round tube, using a series of shaping formers and a welding process. Following this, the tubes undergo a heat treatment procedure where they are subjected to temperatures above 1000°C. This step is integral in relieving any stress within the metal that might have occurred during welding, thereby improving the tube’s mechanical properties and enhancing its resistance to corrosion. This careful, methodical process forms the basis for a highly durable and resilient EP tube.

The next phase in crafting these robust tubes involves the fascinating process of cold working. In this stage, the heat-treated tubes are meticulously drawn over a mandrel and through a series of carefully sized dies. This process doesn’t merely alter the shape of the tubes, it also enhances their hardness and tensile strength. The effect is a sturdy tube, its diameter and wall thickness precisely decreased, boasting an exceptional level of durability. This artful combination of pressure and control allows the formation of a tube that can withstand tough environments while maintaining its high performance.

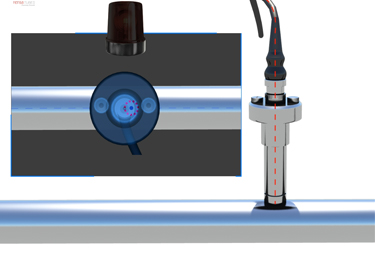

The quest for perfection continues as the tubes face rigorous testing and scrutiny. This phase sees the application of eddy current tests, ferreting out even the tiniest imperfections that might compromise the tube’s integrity. Hardness tests are also employed to authenticate the enhanced mechanical properties of the tubes, confirming their durability. Additionally, hydrostatic tests are carried out to ensure leak-proof functionality, a key quality for any high-stakes application. This thorough examination guarantees the tubes comply with the strictest industry standards, reinforcing their reliability in a multitude of demanding scenarios.

Electropolishing, the defining stage in manufacturing stainless steel EP tubes, is an intricate electrochemical process. It works by meticulously eradicating a thin outer layer from the tube’s surface. The outcome? A smooth, mirror-like finish, nothing short of immaculate. But this process doesn’t merely enhance the aesthetic appeal. The high-quality surface, in fact, deters particle adhesion, amplifying the tube’s resistance against corrosion. This meticulous process ensures the tubes are primed for use in high-purity applications, delivering an unparalleled level of cleanliness that is critical to many industries. It’s the electropolishing process that propels these tubes from being good to becoming the best.

The practical applications of stainless steel EP tubes are found where clean environments are non-negotiable. In the semiconductor manufacturing industry, these tubes are instrumental in transporting high-purity gases. In the realm of pharmaceuticals and biotech, these tubes safeguard sterile conditions in fluid transfer systems, ensuring the safe creation of life-saving solutions. In the food and beverage sector, they are used for processes requiring the strictest levels of hygiene. With their robust durability and impeccable cleanliness, these tubes have become an integral part of multiple industries, effortlessly meeting the demand for high-performance and purity.

As the industrial world acknowledges the imperative of contamination control and high purity, the appeal of stainless steel EP tubes is only bound to surge. Upcoming breakthroughs in material science and engineering are set to boost the performance features of these stalwart tubes even further. In this ever-evolving landscape, it is unequivocal that these tubes will uphold their pivotal role across multiple sectors. Whether it’s underpinning sanitation in food production or safeguarding the sterile conditions in pharmaceutical processes, these tubes are set to carry on making indispensable contributions. In essence, the trajectory of stainless steel EP tubes paints a picture of an exciting future steeped in innovation and growth.

Rensa Tubes manufactures the best high-quality stainless steel electropolished tubing(EP Tubes) in India for Pharmaceuticals, Bio-pharmaceuticals, Healthcare & Cosmetics, Food & Beverage and Dairy industries over in India, 20 + years of experience & expertise.

We are ISO & A3 certified, every electropolished tubing stainless steel or fitting at Rensa undergoes 14 quality tests. that gives great sustainability and anti-water quality long duration.

It’s critically important to choose the right quality of tubes that get installed in the fluid transfer lines. Our technological know-how combined with our experience results in the production of stainless steel tubes of the highest quality comparable to the global standards.

Our mission is to provide hygienic and ultra-high purity stainless steel tubes for various sterile, aseptic and sanitary applications by complying with various global standards and specifications.

Rensa Tubes manufactures the best high-quality stainless steel electropolished tubing(EP Tubes) in India for Pharmaceuticals, Bio-pharmaceuticals, Healthcare & Cosmetics, Food & Beverage and Dairy industries over in India, 20 + years of experience & expertise.

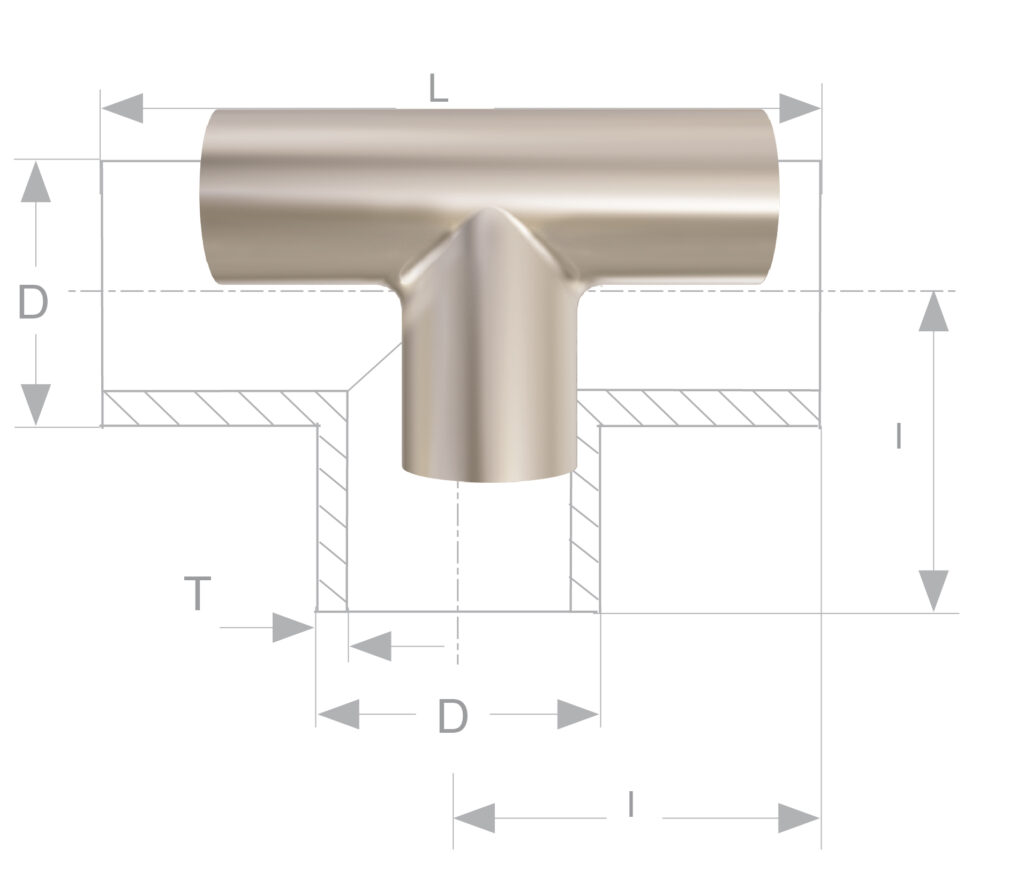

The final quality of our tubes is the sum of our focus on the quality at many stages of manufacturing process, production, workmanship, material, machine and more. Be it the process of Bright Annealing, easy traceability to the raw materials batch or matching and exceeding the global standards like ASME-BPE, ISO-SMS, BS or being certified for 3A, ISO, W0 etc. there are many reasons for you to choose our tubes and fittings.

Rensa – We are a leading manufacturer and supplier of Electropolished Tubes (EP Tubes).

Head Office:

609, Sanket Heights,

Sun Pharma Road,

Vadodara – 390 020.

Gujarat, INDIA.

Telephone : +91 8347 000 368

WhatsApp : +91 8347 000 368

Email : marketing@rensatubes.com

609, Sanket Heights,

Sun Pharma Road,

Vadodara – 390 020.

Gujarat, INDIA.

Telephone : +91 8347 000 368

WhatsApp : +91 8347 000 368

Email : marketing@rensatubes.com

Plot No. 13 & 14

Jhagadia G.I.D.C.,

Bharuch – 393 110.

Gujarat, INDIA.

WhatsApp : +91 8347 000 368